RELATED PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

As a leading single source provider of turnkey processing and packaging lines, ProMach efficiently and cost-effectively helps customers of all sizes ship more packaged goods out the door. Our global team of technical application and engineering experts can transform individual pieces of equipment into high-performance production lines and help mitigate risk by partnering with customers to provide everything from line design to the end of the line.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreFeatures & Options

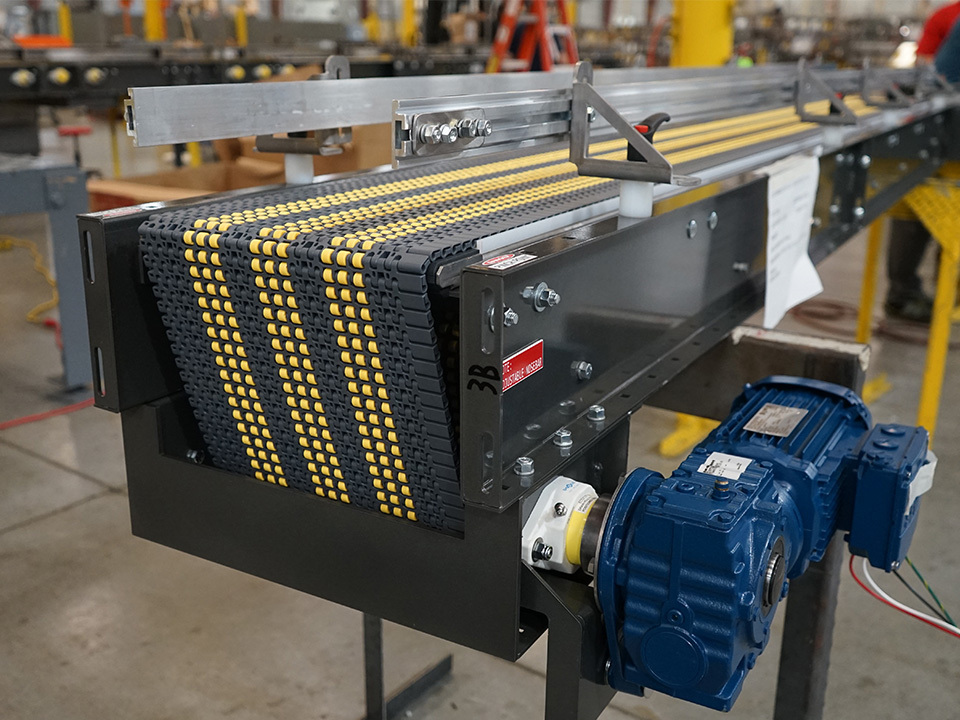

- 11 Gauge Construction

- 2.5" Square Bore Thermoplastic Conveyor Sprockets

- 2 Eurodrive Constant Speed Parallel Shaft End Mounted Drive Motors

- Dual #60 Roller Chain

- Formed 11 Gauge Supports

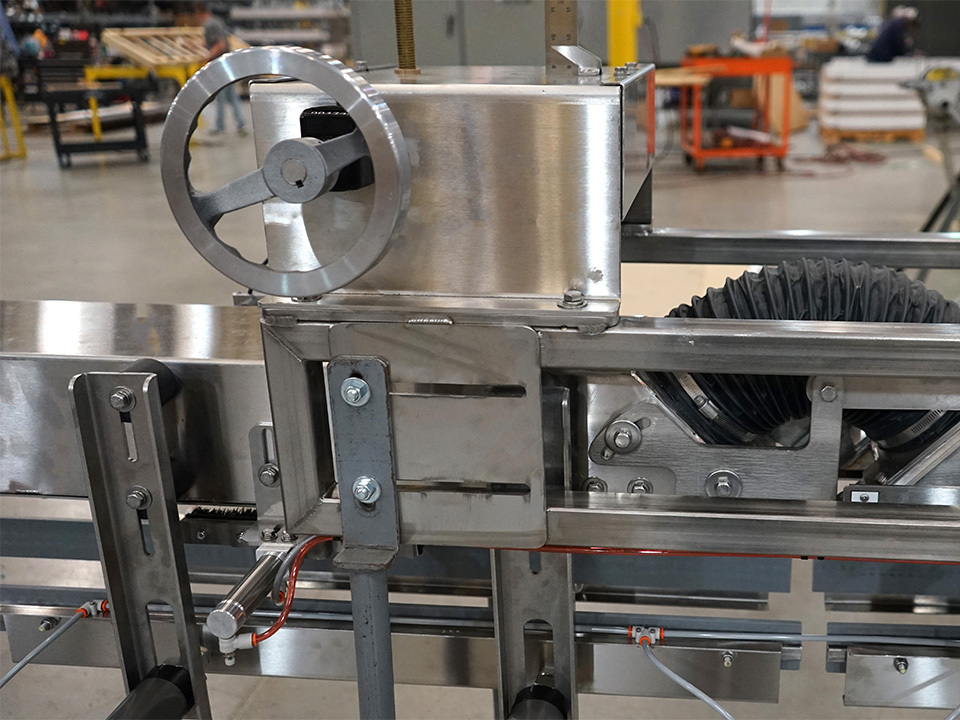

- 11 Gauge Formed Stainless Steel Backstop

- Polished Stainless Steel or Painted Carbon Steel Construction

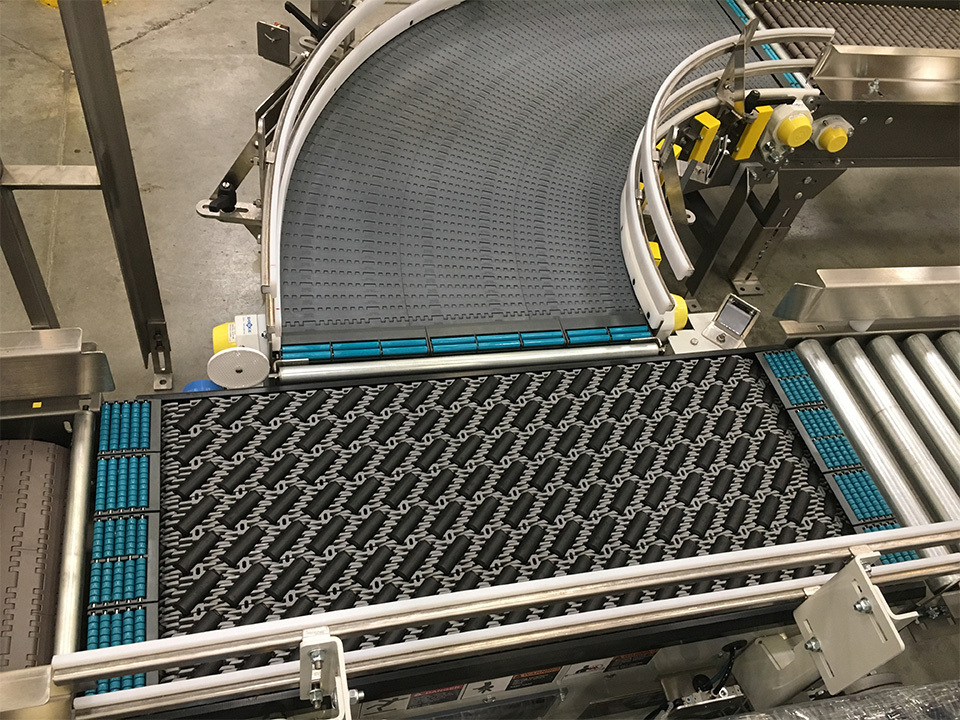

- Bi-Directional, Uni-Directional, or Inline Accumulation